|

| January 17, 2012 | Volume 08 Issue 02 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Specialty tapes help electronics/aerospace industry prevent fire propagation

Polyonics has recently introduced a family of flame-retardant tapes that have been tested for compliance to the UL94 VTM0, FAR 25.853 flame-retardant and BSS 7238/7239 smoke and toxicity standards. These tapes have proven to help aerospace customers prevent fires in avionics.

The risk of fire from electronics, electrical, and electromechanical devices (batteries, power supplies, motors, etc.) is real and not going away. This is especially true in avionics where more power is being housed in smaller spaces, duty cycles are ever increasing, and the need to protect lives is paramount. Designing with materials that do not propagate fire, such as flame-retardant tapes, effectively addresses this need.

Understanding how polymers burn

Engineers at Polyonics (Westmoreland, NH) understand the chemistry and combustion of polymers and have developed a wide variety of flame-retardant tapes to address a spectrum of applications. These tapes help prevent the propagation of fire through the company's unique FlameGard technology. The technology includes advanced resins, polymers, and adhesives that both increase the dimensional stability of the tapes and create a unique char layer that acts as a heat shield to:

- Lower temperature;

- Remove oxygen;

- Reduce concentration of flammable gasses;

- Slow rate of thermal oxidation;

- Minimize thermal degradation; and

- Prevent propagation of fire.

The chemistry of burning

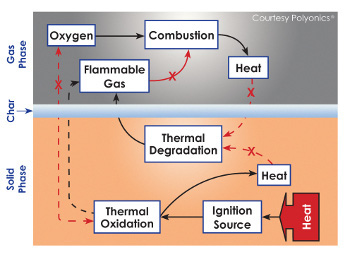

The burn-cycle diagram depicts how heat contributes to burning (combustion). It also illustrates the areas (X) where the chemical mechanisms, incorporated in the Polyonics FlameGard technology, actively help retard the burn cycle.

Burn-cycle diagram: Chemical mechanisms that help retard burn cycle.

Heat causes thermal degradation of polymers, which in turn generates flammable gasses (fuel). Burning occurs when this fuel combines with oxygen in the presence of an ignition source. The process generates additional heat and gases creating a self-sustaining burn cycle.

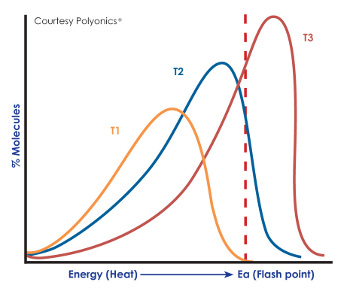

The temperature chart illustrates the role temperature plays in accelerating this cycle. At temperature (T1) very few of the molecules (area under the curve) have enough energy (activation energy Ea) to burn. Adding more heat raises the temperature to (T2), causing more molecules to have enough energy to become fuel and burn.

Temperature chart: Temperature's role in accelerating combustion

At (T3), the majority of molecules have become fuel and a sustainable fire is likely. Conversely, if the temperature can be lowered from (T3) to (T1), the fire will self-extinguish. Polyonics employs resins and polymers that are dimensionally stable and don't generate significant amounts of flammable gasses when exposed to heat and flame. In addition, upon initial combustion, the fire-retardant tapes create a char layer (see burn-cycle diagram) that acts as a heat shield (physical mechanism) slowing the rate of thermal oxidation and reducing thermal degradation.

Polyimide, polyester, aluminum tapes

The single-coated, linered tapes include 1- and 2-mil polyimide and 2-mil polyester films and 2-mil aluminum foils. One tape also includes ESD HardCoat electrostatic dissipative properties using Polyonics' proprietary TriboGard technology. Other custom constructions are readily accommodated. The tapes include a wide variety of liners to complement different die-cut processes.

Best to test tapes in customer's environment

Aerospace flame problems are complicated and, with few proven solutions available, we know that many engineers and manufacturers can get frustrated looking for solutions. Hopefully, these tapes provide an answer for some applications.

Review the specs and select the best tape(s) for your application here.

You can also request Polyonics samples here.

Address specific questions to Dave Genest, Tape.Expert@polyonics.com.

Source: Polyonics

Published January 2012

Rate this article

View our terms of use and privacy policy